News

PERFORMANCE UNDER PRESSURE ON THE ROAD

In the quest for added performance, many road cyclists have fallen prey to myths about tyres. Not so long ago, competitors chose the lightest, thinnest possible tyre, inflated to a rock-hard pressure. Racing men of all sizes used to boast that they always put nine bars into their tyres. Even though they were prone to “snakebite” punctures, inflicted by the very rims which held them. But nowadays there is a wealth of reliable research findings on tyre performance. The myths have been debunked – and thin tyres pumped up to bursting point are no longer seen as desirable for every purpose.

Some tyres of medium-to-large cross-sections give a more stable contact patch on the road – which imparts better balance and control, let's say in a crowded peloton on a twisting criterium course. For a stage event where the rider remains in the saddle for several hours each day, comfort is an important consideration. A racer on hard, skinny tyres may suffer sapping discomfort and perform far below his best level. These aspects are well to the fore in “Eroica” events ridden on gravel, and wise entrants choose a tyre which will meet their needs for comfort and control.

Then there is the question of what happens when the rubber meets the road – and rolling resistance. This can be measured in watts and added to the total aerodynamic drag figure for the bike and rider acting together. Fat, soft tyres have high rolling resistance – but the lowest figures are to be found in tyres of moderate dimensions. Elasticity, lightweight and a well-chosen pressure can do a great deal to less rolling resistance in both slim and fat tyres. It has been noted that a fatter tyre at a lower pressure can equal – or even beat a slimmer tyre's rolling resistance.

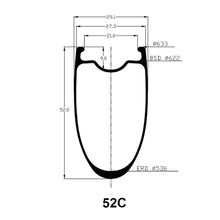

There are many tyre variables to optimize, and pressure is only one of them. Apart from the weight, composition of rubber and pattern of the tread, we must take the type of tyre into account: clincher with inner tube (standard or latex); tubeless clincher; tubular with latex inner; and all cross-sectional dimensions, say from 23mm to 37mm. One rule becomes immediately apparent – as tyre cross-section increases, optimum pressure goes down, measured in psi (pounds per square inch) or bars (of atmosphere).

Tested in the lab, a tubeless 25mm time trial tyre of 240 grams and cotton casing with 320 threads per inch can achieve a rolling resistance of only 7 watts. That's at an air pressure of 8.3 bar or 120 psi. At the same pressure, a lower-priced all-around 400-gram tyre with an anti-puncture compound in the inner tube may have a rolling resistance figure of 20 watts. All well and good, but what must change if we attach wheels to a bike and add the rider? The heavier the combination, the higher the pressure; if this takes a big rider out of his comfort zone, he may shift to a fatter tyre and get the performance he needs at a lower pressure.

Okay, here's the nitty-gritty on the optimum tyre sizes and pressures for three cyclists, with masses of 60kg/132lb; 85 kg/187 lb; and a big guy of 110 kg/242lb. With a 23mm tyre, Mr. Small uses 7 bar, Mr. Medium puts in 8 bar, and it will take 9 bar to keep the large cyclist happy. As the tyres get bigger, the pressure sinks. Here are the figures for the short guy: 25mm needs 6 bar, 28mm takes 5.5 bar and if he's pounding the strade Bianchi on 37mm gravel tyres, only 4 bar/50psi will be necessary.

For 25mm tyres, Mr. Medium should use 7 bar/115 psi and for 28mm, 6.5 bar/94psi. The 37mm tyre requires as little as 5 bar/ 72psi. The tall cyclist needs heavier pressures for every cross-section: he's down to 8 bar/115psi with a 25; 7.5 bar/108psi at 28mm and only 6 bar/87psi with 37mm covers fitted.

Treat these figures as a rough guide, and keep on experimenting until you find the pressure that's right for you, your bike and your sport. There is one purchase which is absolutely necessary for your pursuit of performance – a track pump. If you've never had one, you're about to discover a new world of precision, convenience, and repeatable results. A frame-fit or mini-pump is useful when you puncture out on the road – but that's all they're good for. What you need is a vertical track pump with one or two barrels and an accurate pressure gauge reading in psi or bar.

Such a pump can inflate a tyre to 9 bar in a dozen strokes. It should be part of your daily routine, as you lower the pressure in training tyres for rain-soaked or rough roads – or increase it for a set of high-performance wheels on race day. Check pressures every few days, or if the weather has been hotter or colder than usual. Looking after tyre pressures will give you greater mileage, on top of any speed gains you may achieve.

When the tyre is new, carefully note the maximum pressure it was designed for – printed on the sidewalls as psi or bar. NEVER exceed this pressure with your powerful track pump – unless, of course, you're trying to make the tyre explode! Be gentle with the presta valve, both when unscrewing it and doing it up again after inflation. This little part can be fragile if handled clumsily as you attach the track pump lock to it. Read the instructions with care.

When you shop for new tyres, you should know what the best combination is for your weight, and be guided by the maximum rated pressure. Short riders can take a more relaxed attitude, but the big guys should never buy a 23mm tyre which they'll have to run at its rated maximum or even above that. Nobody enjoys it when a front tyre blows out! Go bigger if you have to stay within the pressure limit for your weight.

For those in doubt, ICAN has published online recommendations for tyre pressures to be used by riders in four weight categories and several types of tyre. These very useful figures come along with the specifications for ICAN carbon wheelsets.

36 comments

-

Posted on by

-

Posted on by

-

Posted on by

-

Posted on by

-

Posted on by

- Previous

- 1

- 2

- 3

- …

- 8

- Next